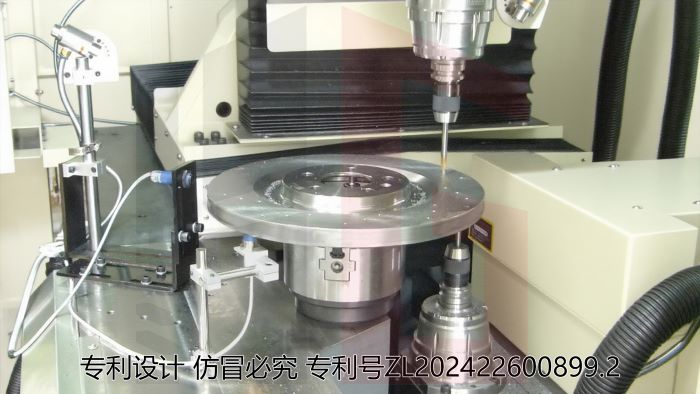

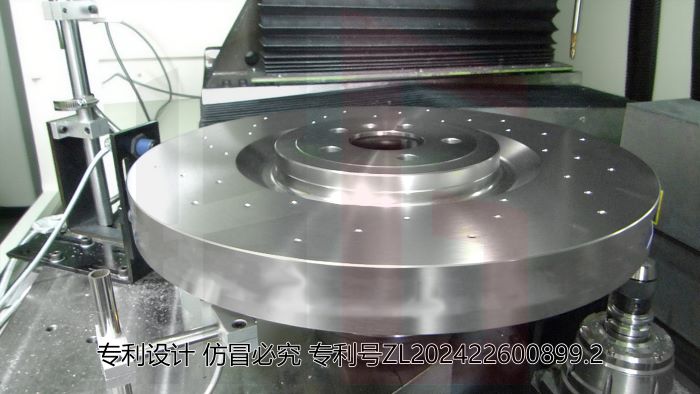

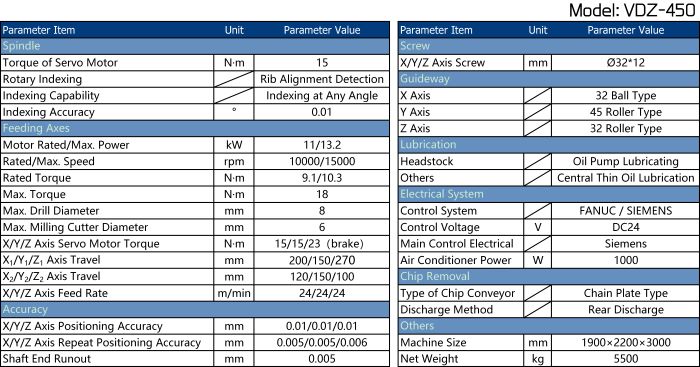

The VDZ-450 Brake Disc Double-Side Drilling Machine is engineered for flexible and digital manufacturing environments. With its modular configuration, it accommodates a range of brake disc types, enabling swift model changeovers and multi-variety production with minimal downtime.

This machine's automated clamping and dual-spindle synchronous drilling significantly decrease manual intervention and cycle times. The VDZ-450 supports real-time process monitoring, remote diagnostics, and integration with MES or ERP systems, enabling full traceability and digital resource management.

In practice, the VDZ-450 Brake Disc Double-Side Drilling Machine works in harmony with automated loading/unloading and inspection equipment. Such integration allows enterprises to build a closed-loop, intelligent production line for brake disc components, enhancing quality and operational transparency.

Smart features such as remote management, predictive maintenance, and parameter auto-adjustment position the VDZ-450 as a key component in the transition to Industry 4.0. Manufacturers gain the agility to react swiftly to market changes and new production requirements.

Overall, the VDZ-450 Brake Disc Double-Side Drilling Machine demonstrates how precision, automation, and intelligent connectivity can drive efficiency and innovation for automotive brake disc manufacturing.