Hengga Intelligent to Attend Canton Fair, Highlighting Brake Disc Lathe Technology

2025-03-22

The brake disk dedicated machine is a type of machine tool specifically designed for processing automobile brake disks. It can achieve efficient, precise, and automated production of brake disks. By improving the accuracy and quality of brake disks, it also improves the braking performance and safety of automobiles. So, what is an automobile brake disk? And what is its function?

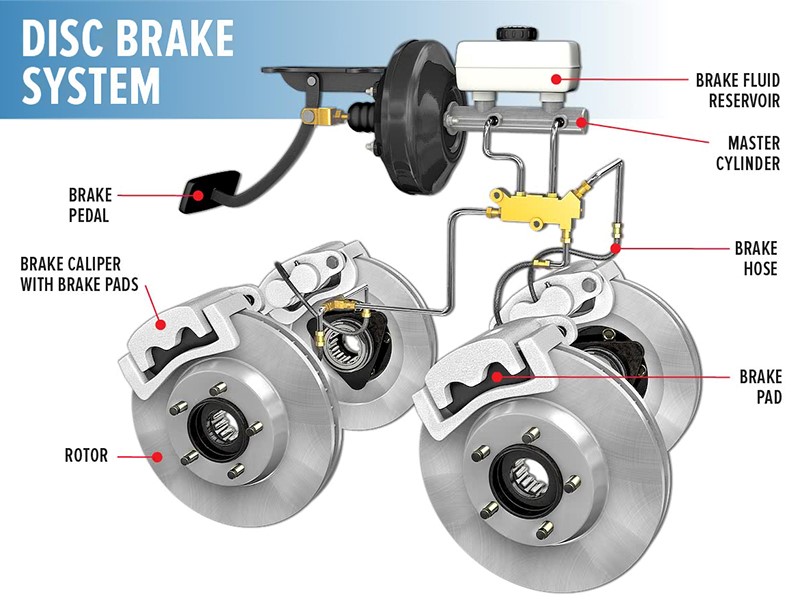

Disc brake system

The automobile brake disk is an important component of the automobile braking system. It is used in conjunction with brake calipers and brake pads to convert the kinetic energy of the car into thermal energy through friction, thereby slowing down or stopping the car. Automobile brake disks are usually made of materials such as cast iron or carbon ceramics, and are shaped like a round flat disk, which is installed on the hub.

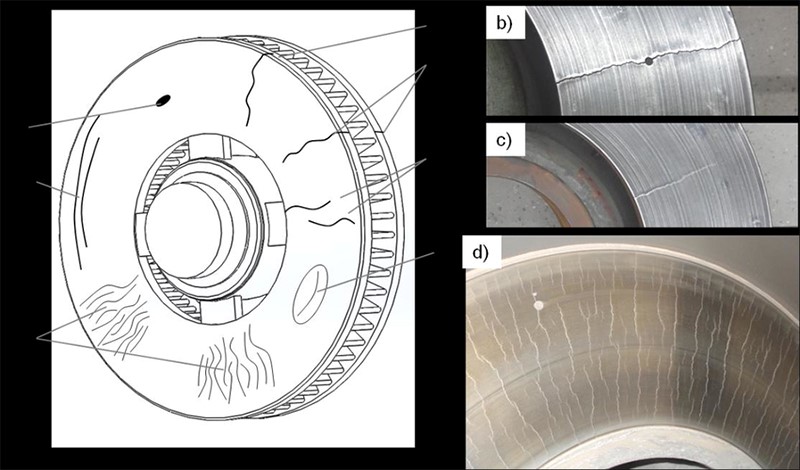

The quality of automobile brake disks directly affects the driving safety and comfort of the car. If the surface of the brake disk is uneven, not smooth, or has defects such as cracks or deformation, it can cause problems such as poor braking performance, increased noise, and increased vibration. It may even cause serious traffic accidents. Therefore, it is necessary and important for automobile manufacturers and maintenance personnel to choose a high-quality brake disk CNC machine tool to process and inspect brake disks.

Brake disks with defects

There are various types and specifications of brake disk dedicated machines, which can be divided into single-spindle brake disk dedicated machines, double-spindle brake disk dedicated machines, and dual-tool-position brake disk dedicated machines according to different functions and structural characteristics. Among them, the double-spindle brake disk dedicated machine uses a spindle positive and negative combination, and is equipped with an automatic loading and unloading device and a mechanical hand to transfer workpieces. It can complete the processing of all internal and external surfaces without turning the workpiece, and automatically output the materials. The dual-tool-position brake disk dedicated machine uses two tool holders to process the workpiece at the same time, and has adaptive functions, which improves production efficiency while ensuring accuracy and surface quality.

Various brake disk dedicated machines

Regardless of the type of brake disk dedicated machine, the stability of the machine body structure, the precision of the spindle structure, the durability of the guide rail screw, and the lubrication system are emphasized in the design and manufacturing process. The advantages and functions of brake disk dedicated machines are not only reflected in the processing of brake disks themselves, but also in the enormous benefits they bring to the automobile manufacturing industry. First, brake disk dedicated machines can improve the processing quality and consistency of brake disks, reduce the scrap rate and repair rate, and lower production costs and risks. Second, brake disk dedicated machines can improve the processing efficiency and production capacity of brake disks, shorten delivery cycles, and meet market demand. Third, brake disk dedicated machines can achieve intelligent, automated, and digitized management of brake disks, facilitate monitoring and adjustment of production parameters, and improve production flexibility and adaptability.

In summary, brake disk dedicated machines are specialized, high-end, and intelligent machine tools. They provide reliable, safe, and efficient solutions for automobile braking systems and bring enormous competitive advantages to the automobile manufacturing industry.