Hengga Intelligent to Attend Canton Fair, Highlighting Brake Disc Lathe Technology

2025-03-22

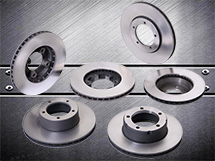

Brake Disc Turning Machine is a device that can perform outer diameter turning on both sides of the workpiece at the same time, effectively improving the parallelism accuracy of the workpiece, reducing 50% of the processing time, and meeting the processing needs of various precision disc-type workpieces such as brake discs.

Brake Disc Turning Machine

Brake Disc Turning Machine adopts vertical guide rail structure, column, base and slide seat are all made of high-grade gray cast iron, column and slide seat guide rail are all quenched by high frequency, and the guide rail moving surface is pasted with plastic to ensure the stability and accuracy retention of the machine tool for long-term use.

Brake Disc Turning Machine adopts high-rigidity short-thick type, servo motor driven spindle, to achieve low noise and low vibration of the machine tool at high speed. It uses high-quality ball screws and linear guides, which make the machine tool have high transmission efficiency, good transmission characteristics, fast and stable tool holder movement, and high positioning accuracy.

Brake Disc Turning Machine has automatic and centralized lubrication system, which can ensure continuous and effective lubrication of guide rails and ball screws, and effectively extend their service life. It adopts dual-channel control system, dual-tool tower structure, and two sets of independent tool towers.

Brake Disc Turning Machine uses multi-language LCD display servo CNC system, which also has tool compensation, manual/automatic return reference point, automatic diagnosis monitoring display functions, truly achieving machine tool integration and automation. It is equipped with chain plate type chip remover to quickly remove iron chips and reduce the thermal deformation effect of iron chip heat on the bed body.

Brake Disc Turning Machine saves floor space and effectively improves system cycle time. It can be automated for a long time without frequent material collection and feeding. It is suitable for batch processing of various disc, hub, flange, engine end cover and other parts with high processing accuracy and dimensional consistency requirements.